Quality

Here at Airmaster we are very proud of the quality of our products. We believe they are the best available in the market today. Easy words to say, but here are some specific areas where Airmaster designs excel.

Hub |Blades | Controllers | Extensions | Spinners | Sliprings

One Piece HubAll Airmaster propellers are designed using a single hub shell. The single shell design is able to distribute stresses evenly within the hub material making a stronger, safer propeller. |

|

|

Painted Hub OuterEach Airmaster propeller is fully machined on the inside, and protected on the outside with two pot epoxy paint. We specifically do not anodise the exterior of stressed parts to reduce the likelihood of fatigue cracking, ensuring a long product life. |

Modular DesignAll propellers conform to a modular design approach. Each major assembly comes out as a complete unit, and there is a high degree of compatibility between product groups. This gives a high degree of option flexibility and greatly simplifying servicing operations |

|

|

Precision Pitch ChangeAirmaster use a proprietary thread design with a closely matched, phosphor bronze guided nut to minimise backlash and inter blade pitch error. This ensures smooth, flutter free operation for the entire life of the propeller. |

Ultra Quality PC MotorPitch change actuation is achieved with ultra-precision DCX servo gear-motors from Maxon (Switzerland). These motor drives are simply unsurpassed in build quality and long life performance. More on Maxon> |

|

|

Easily Adjusted Pitch Change StopsIndividual pitch stops are provided for the Fine / Coarse / Feather limits. All the pitch stops are easily adjusted from within the top of the hub to allow each propeller to be tailored to the specific conditions of your engine and flying environment. |

Blades

Controllers

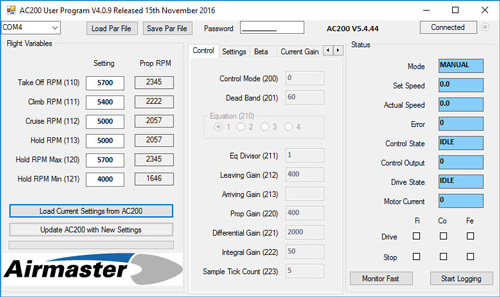

Easy to OperateThe AC-200 electronic governor is extremely easy to operate with simple selection of engine speeds for the common modes of flight, Take Off, Climb and Cruise. Further speed adjustment is possible by the use of the Hold function which selects engine speed in a similar way that cruise control is used in a car.

|

|

|

Precise Speed ControlAdvanced software techniques are used within the AC200 controller to achieve fast and precise speed control, that are just not available in traditional propeller governors.

|

Instant Pilot FeedbackThe pilot is always aware of the correct propeller operation, thanks to the clear feedback indicators. The unobtrusive but meaningful display confirms correct movement of pitch change mechanism, when a pitch limit is reached, confirmation that a speed signal is present, as well as any possible fault indication

|

|

|

CustomisableThe AC200 is an extremely versatile control system that can be used with a wide variety of engine types. All parameters are configurable including the engine set speeds which can be set by the user with any Windows PC. In addition the controller can communicate with external telemetry systems (as used for UAV operation). Operational data can also be logged for service purposes.

|

Extensions

Flexible Mount OptionsAirmaster manufactures a large range of spacers, extensions and adapters to make sure the propeller fits you’re your aircraft perfectly.

|

|

|

Precision MachinedAll extensions are machined in house on our 5 axis Integrex mill-turn, from high grade billet aluminium to ensure concentricity and neat fit. |

Corrosion ProtectedAll extension types are protected from the elements in an applicable way.

|

|

|

High Grade HardwareAN (mil-spec) hardware is used throughout the mounting range to ensure consistent quality and easy part replacement. Nordlock washers are used to guarantee long life vibration resistance

|

Simple InstallationIncluded with each extension assembly are specialist tools that simplify insertion and extraction of the propeller flange drive lugs.

|

|

Spinners

Huge RangeAirmaster provides a large range of spinner models, to fit any aircraft type. Current range includes

|

|

|

Choice of FinishThe ideal finishing touch to your aircraft is a perfectly formed spinner. Airmaster spinners are available in a number of finishes. Highly polished aluminium, matte aluminium ready for painting by you, or painted gloss white by us.

|

Perfect BalanceAirmaster spinners and backplates are made from sheet aluminium to ensure they are straight and perfectly balanced. They come fully finished and fitted from the factory.

|

|

|

Precise FitTo ensure the spinner remains completely centralised, an adjustable front support is incorporated into the head of the hub. This can be used to completely eliminate any lateral play in the spinner cone, reducing any possible stress on the spinner backplate.

|

SecureAll spinner mounting screws are anchored by aviation grade riveted nut plates to ensure vibration does not work the screws loose.

|

|

|

Easy InstallAll Airmaster backplates have pre-drilled holes in convenient locations to accept balance weights, making dynamic balancing a breeze.

|

Sliprings

Long LifeAll Airmaster sliprings are made from durable materials to give a long life and reliable operation.

|

|

|

Multiple OptionsAirmaster manufactures multiple slipring sizes and styles to give maximum flexibility.

|

Compact DesignThe matching brush head includes 3 electrical circuits + 1 speed sensor all in a compact package. The same bush head fits both the large and small slipring designs.

|

|

|

Simple InstallationComplete mounting kits including all the brackets and hardware are available for most engine types making installation very straight forward.

|

Easy MaintenanceBrushes are very easily replaced using basic soldering tools. An extra set of brushes are included with the propeller on purchase and subsequent sets available at a low cost.

|

|